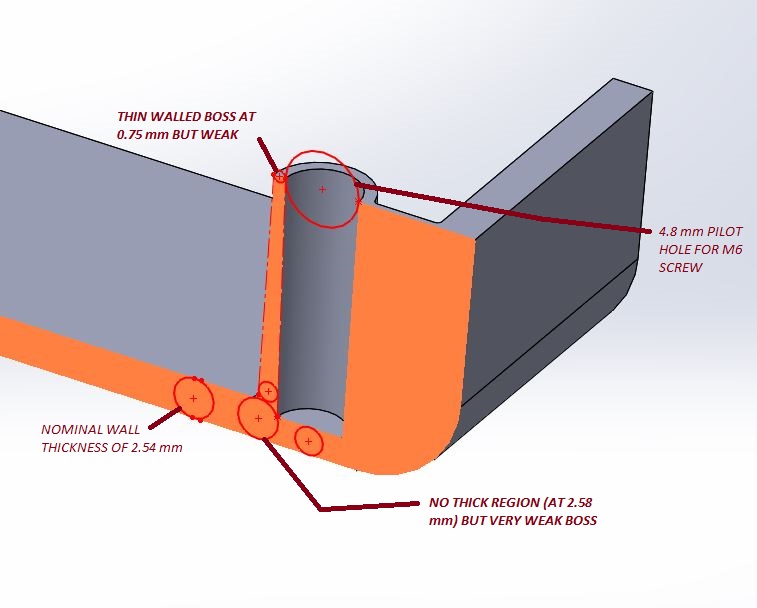

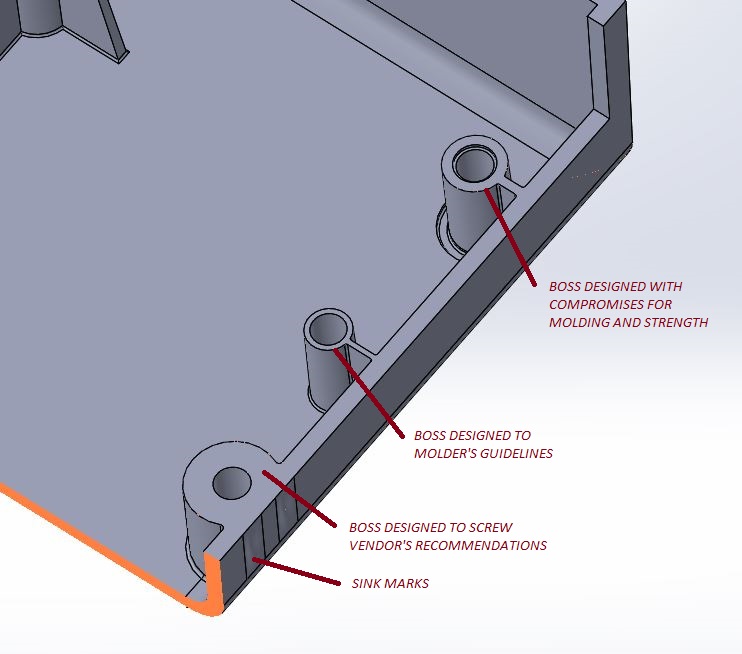

How come the screw boss crack after mold-in screw insert? | I am a Manufacturing Process Engineer (MPE)

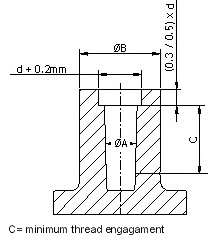

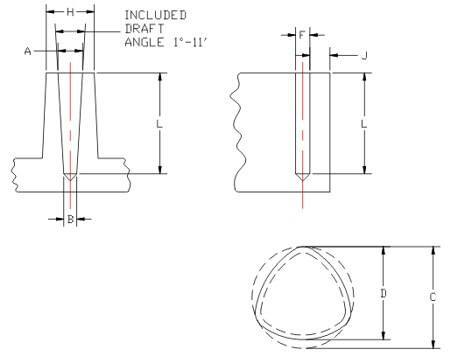

Thread forming process in polymeric bosses using self-tapping screws.... | Download Scientific Diagram

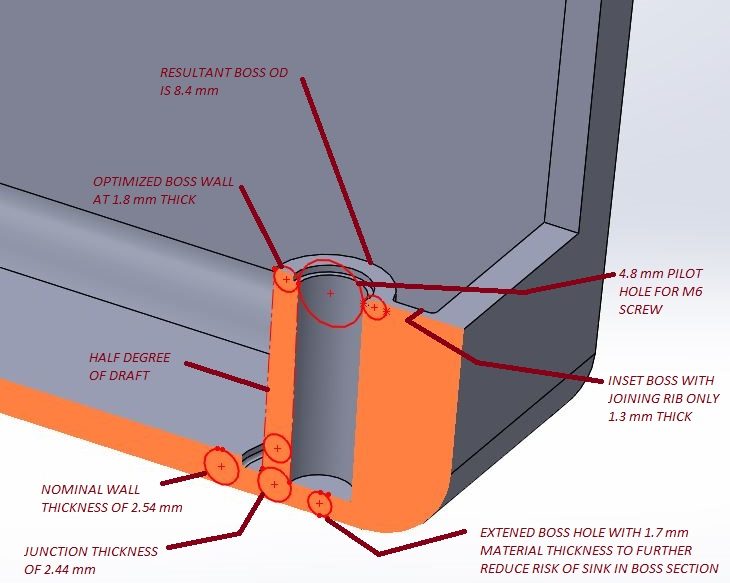

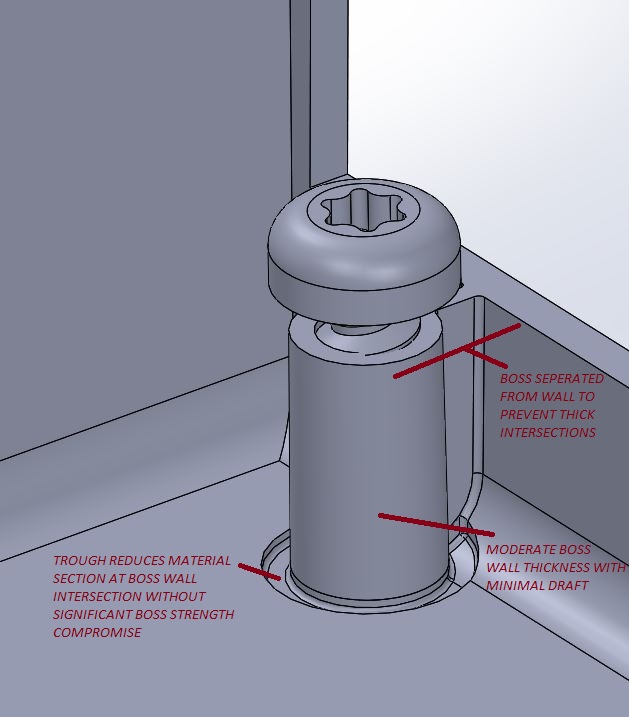

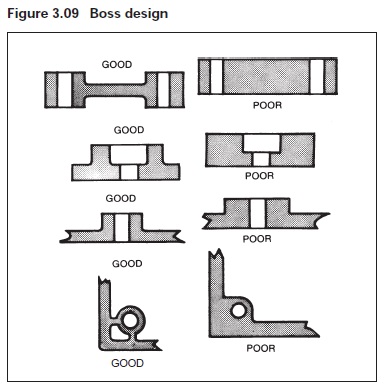

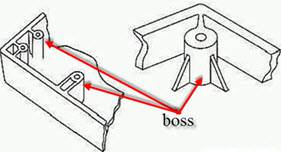

A correct boss design is very important in every plastic part | Professional industrial design services, High value-added mold and High quality product suppliers